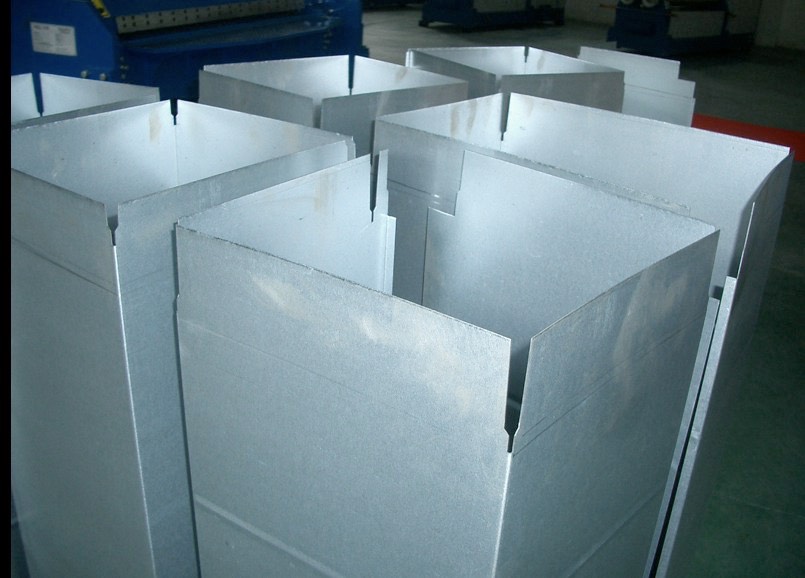

Duct Line 3 in Shop

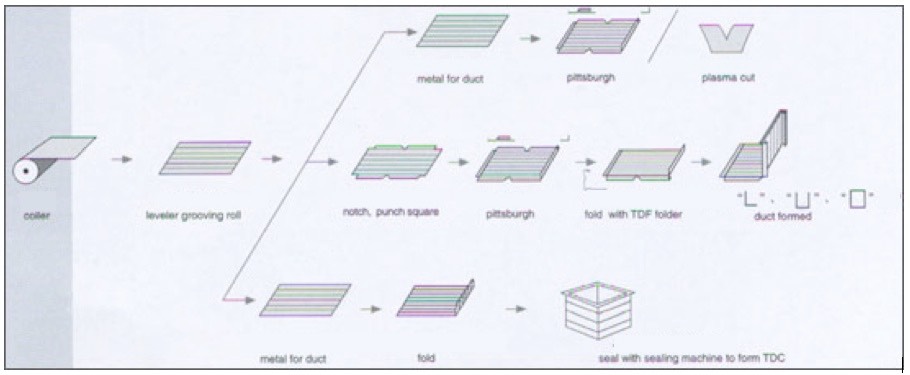

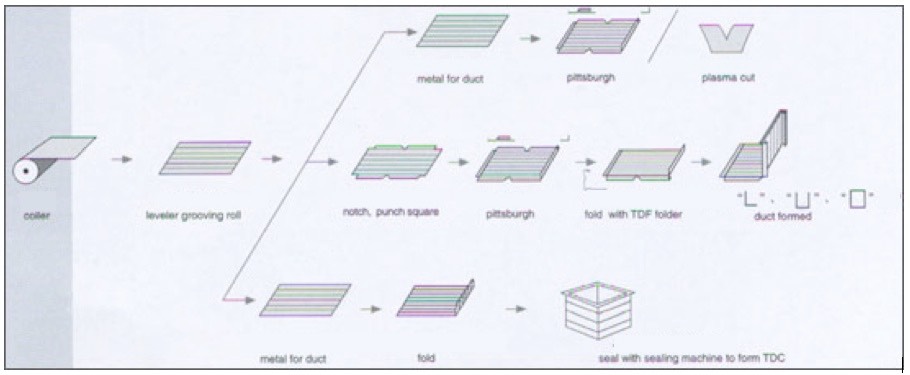

PLC controls when the punches operate to cut notches in metal.

Technical Details:

- Material Thickness: 0.5mm - ´1.2mm galvanized steel 0.4mm - 1.0mm color steel

- Material Width: 48" (1250mm)

- weight of coil: up to 5ton

- ength for cutting: random

- level inaccuracy of length: ±0.02 in. ±0.5mm

- diagonal inaccuracy of steel: ±0.03 in. ±0.8mm

- producing speed: up to 32ft/min (∫≤10m/min)

Electrically operated decoiler -- 11 roller precision leveler and beading -- Hydraulic notch and square cut -- hydraulic cut to length -- hydraulic foling machine. Includes Hydraulic control system and Mitsubishi or ABB programmable controller with touch senstive high resolution color screen.

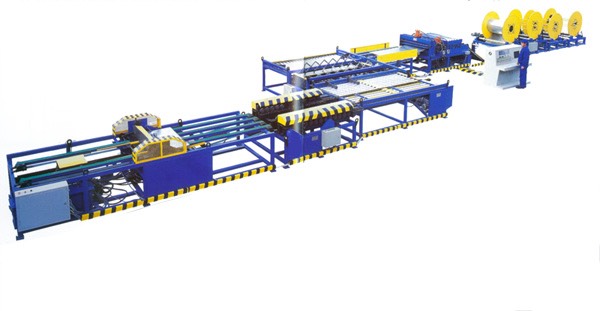

Duct Line 5

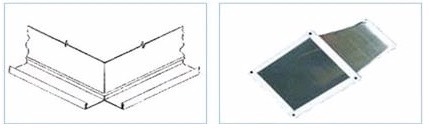

Fully Automated Duct line with TDF and Pittsburg lock for complete duct manufacturing.

This line can put pittsburg lock for air tightness of seam as well as TDF flange on ends of duct sections.

This automatic duct line has decoilers, leveling rollers, grooving roll, hydraulic notch and punch stations, hydraulic shear, amoveable pittsburgh lock machine, duplex transverse flange manufacturing machine, TDF hydraulic folder and CNC system. It si possible to product square ducts as small as 200mm x 200mm (8" x 8").

Width of the line 14.8 ft. 4.5m

Total length 82 ft. 25m

Max. thickness of strip 1.2mm

Max Strip speed 50ft/min 15.8m/min

Pipe length 48 in. 1250mm

Cut to length 600mm----3000mm

Total power 35kw

Total weight 26,500 lb 12000kg

Operators :four or five persons, one person work to control, two person for adjust

and set mould ,the one person for the last process